PRODUCT CATEGORIES

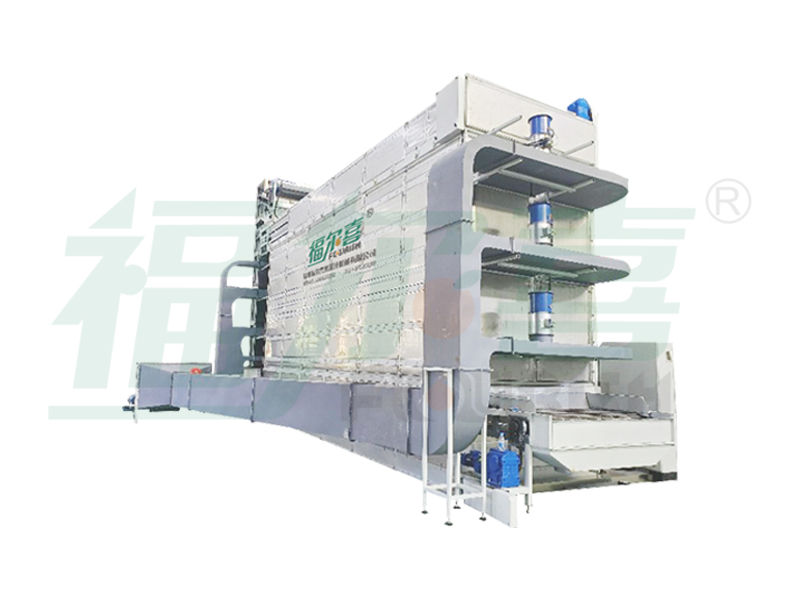

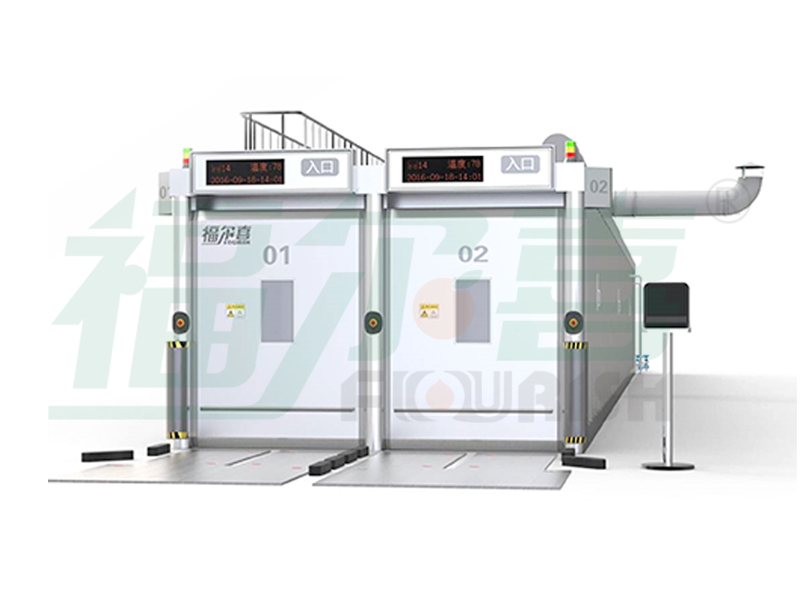

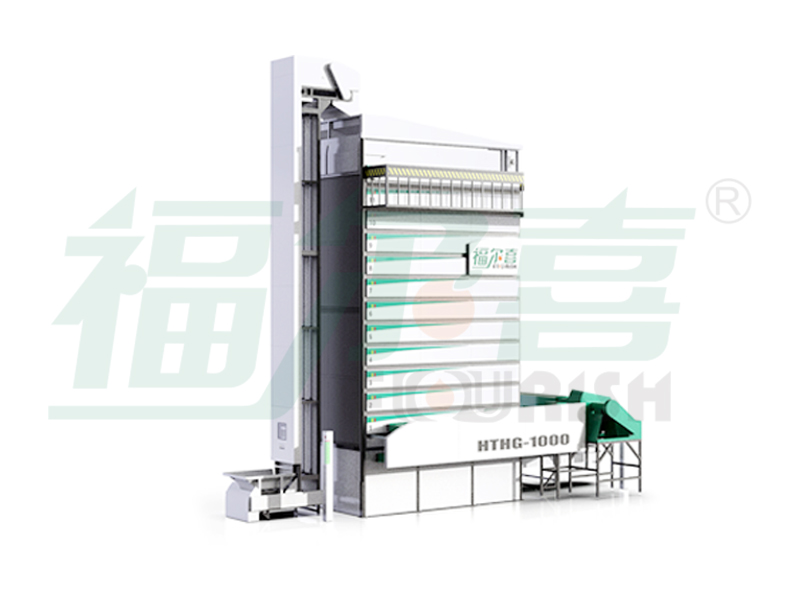

Intelligent full circle drying chamber

This innovative equipment is a key machine of Flourish. It can ensure products quality, high efficiency, intelligence control and low maintenance cost.

Application:

Walnuts, Date, Cherry Tomatoes, Pepper, Chinese wolfberry, Banana slice, Lemon slice, Chinese herbal medicine, Seafood

Characteristics:

Quality assurance

It can realize sectional temperature control and humidity control. We can set sectional temperature and humidity according to different material characteristics and drying curve that ensure the product appearance and interior quality;

The feeding device adopts flexible skid-plate which can ensure the dried products have good appearance, uniform quality and no damage.

The dryer with humidification is especially suitable for the material of which moisture is lower than the requirement of the products. It can adopt the rehydration technology to balance the humidity of overdrying material automatically;

The skid-plate adopts food grade material of which thermal conductivity is close to fruit &vegetable material so as to prevent fruit &vegetable peel from scald and ensure food safety;

Improve production efficiency

Patented skid-plate structure can realize the material can be spread in the upper and lower layer of the same conveyer. Unique skid-plate structure can double the capacity of drying equipment comparing with common net chain dryer, which can make full use of space;

The steam radiator is uniform arranged in the dryer interior to ensure the temperature uniformity of all parts of the dryer.

Intelligent control

It adopts the PLC control. We can independently set the sectional temperature and humidity and the system can adjust the these data to set value automatically;

It can ensure continuous feeding. When feeding interruption, the dryer can stop automatically; when feeding normally, the dryer can open automatically;

If the material level shows the feeding material finish, the dryer can alarm automatically and the feeding material is stop automatically;

Easy maintenance

The damage of skid-plate is only required to replace the damaged plate, just less than 2 minutes, so it is convenient maintenance with low cost.

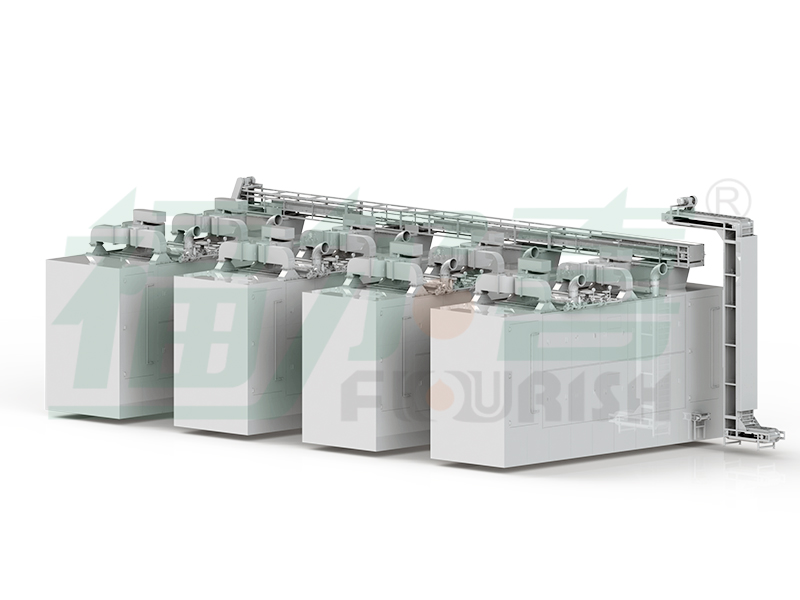

Seamless integration

It can match with the other equipment to form the whole automatic production line;

Various heat source: coal, natural gas, oil, electricity, etc

Various heating methods: hot air, steam, heat conduction oil, etc

LOCATION :

LOCATION :

Order Now

Order Now Collection

Collection