PRODUCT CATEGORIES

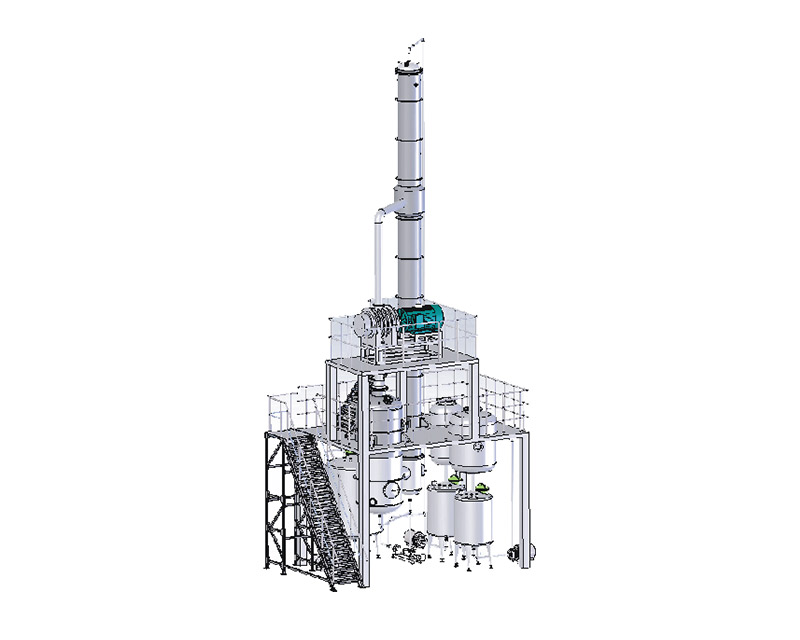

Five advantages:

● flash technology

Before concentration after sterilization, the system is equipped with two-stage flash evaporation, with the purpose of:

a: The cooling time of material after sterilization is shortened;

b: Flash evaporation process improves concentration efficiency;

C: Through the control of flash temperature, 3% ~ 5% alcohol in juice is eliminated.

● reliability

Compared with the traditional three effect evaporator:

a: The process path is shorter, the system quickly establishes the heat balance, and the debugging is fast;

b: The whole system has simple structure, few components and low failure rate;

c: Low requirements for operation.

● food hygiene and safety

Compared with the traditional three effect evaporator:

The system only changes the way of heating and heating. The flow of the material side is the same as the traditional three effect evaporator. The material side is in the tube and the heating steam is outside the tube. The material will not be polluted and there is no risk of food safety and health;

● low temperature concentration

The highest safe temperature of the heat sensitive material is selected as the evaporation temperature, which ensures the original nutritional composition and flavor of jujube juice. However, the traditional three effect evaporator can not achieve only one evaporation temperature, but only realize the step evaporation. There must be a part of the temperature higher than the safe temperature, which will lose part of the nutritional composition of the material. Evaporation temperature can be set according to different material characteristics.

● energy saving

Because of the secondary steam compression technology, the system realizes the overall recovery of the latent heat of the secondary steam, and achieves the purpose of high efficiency and energy saving. Compared with the traditional three-way evaporator, the energy saving rate is more than 65%.

Performance features:

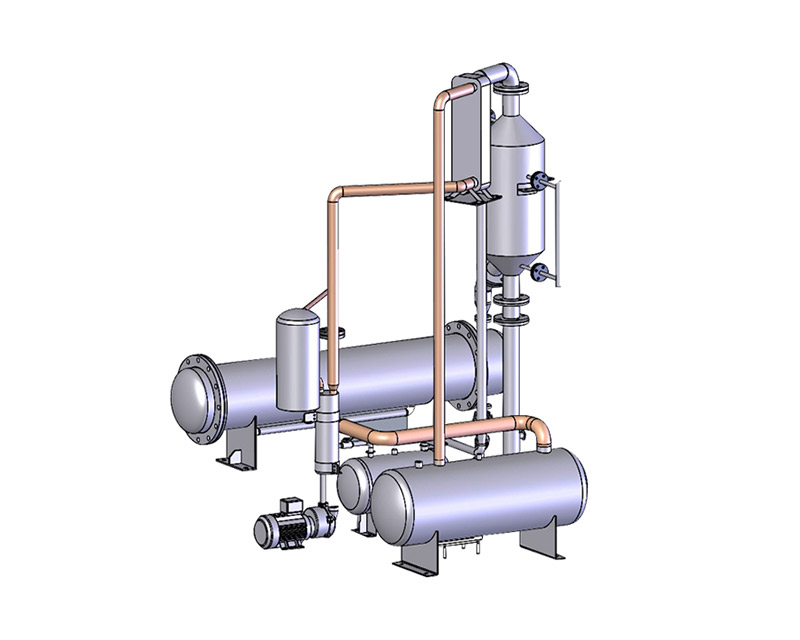

Concentration of fruit juice and liquid food with Flash and Low Temperature Vapor Recompression technology

The concentration of fruit juice and liquid food adopts the technology of low temperature steam recompression system

This type of evaporator will collect the secondary steam (for example, from the sterilizer), filter and compress it, increase its pressure and saturation temperature, and then send it to the evaporation heater as a heat source to replace the raw steam for recycling. The potential of the secondary steam has been fully utilized, so as to achieve the purpose of energy saving. Compared with the traditional multi effect evaporation, the total energy consumption of the evaporation technology is more than 70%, and it is an upgrade product instead of the traditional evaporator. The combination of this technology and low-temperature heat sensitive concentration technology solves the problem of maintaining the flavor, taste and color in the deep processing of high value-added agricultural products in the fruit and vegetable industry.

LOCATION :

LOCATION :

Order Now

Order Now Collection

Collection